Time to repair those easy problems I found yesterday. I removed the CPA module and scurried off to the bench. It has a small circuit board that automatically gets a capacitor replaced on it. I had done that weeks earlier. A few minutes work with the meter showed a bad transistor I missed the first time around. I replaced it after crossing it in the Seeburg Cross Reference guide and had it working again shortly. It’s not necessarily a bad thing to have a record clamped when the juke is turned off if when turned on it rotates in the proper direction to play it. The problem comes when it is not and the record plays backward. In a commercial location where no one knows anything about what is happening, an operator might get a call a couple hours after the record played backwards and already disintegrated the needle. So having an auto eject on power up is a good thing.

Second problem turned into a real pain in the butt. This is the volume control with the dead spot. There would not have been any problem had I not been using a remote motor operated volume control. No, the trouble came in finding a suitable replacement. I have several and finally learned another little Seeburg gem. There are two types of late model volume controls when it comes to remote operation. Both have a three pin connector. One type has reject wires going to the three pins.Black and white wires. The other has remote motor voltage going to them. Red and green wires. Got that sorted out as to which type needed and dug one out. Cleaned the pots, ohhmed, connected to the amp and tested.

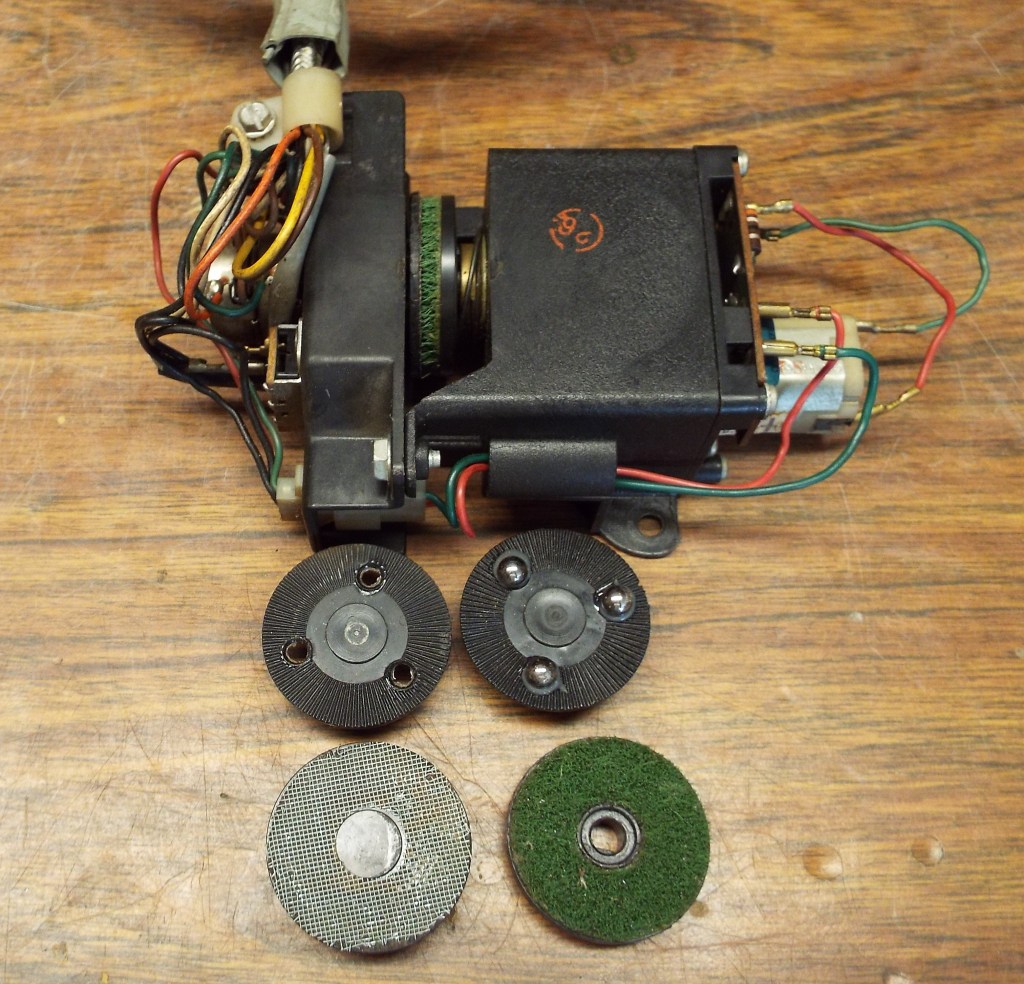

Now for the other half-the motor side. They are coupled one of two ways. One is with steel balls in holes, the other is with a Velcro-type arrangement. Both allow slippage. Not really Velcro or is wouldn’t slip when either end of rotation is reached. I used the 3 ball arrangement with this one like it had on the prior volume control cable. Just a matter of swapping it over to the new cable, eh? Nooo….the motor wouldn’t rotate the volume pots. Just slipped. I pulled the volume side piece up some. It was too close to the housing. When I loosened the two screws holding the halves together the motor would turn the pots. I finally took the spring out from the motor side and cut one loop out of it. This eased the pressure against its other half and allowed the pots to rotate. Only took two hours in 95 degree heat to get this all taken care of.