Look What Followed Me Home

Even a blind hog finds an acorn now and then. This is a nice shiny acorn too! I was perusing the online marketplace as I do every morning and spotted a 1952 Seeburg M100C with a beautiful cabinet done correctly in zebra wood for the low price of $1000. Completely restored these used to go for $5000 all day. The price has dropped a bit since the heydays but this will still turn a nice profit. Dome was good, all chrome looked good. Glass tubes, selector, coin glasses, painted mechanism covers. Has some funky looking pilasters but all the hard work had been done. This from the pictures posted.

I messaged and was able to get a quick response. We talked on the phone and he told me the juke kinda worked, kinda needed some help. I just politely listen. As soon as I saw the juke I knew I’d be going completely through the mechanical, electronic, and electrical aspects. I had a C in Texas that I got for a good price and sold it because I did not feel like doing the cabinet work. With this one having a great cabinet the rest is gravy. Procedures I’ve done many times.

I had to get moving fast. I’ve learned the hard way if one wants something advertised online one should get off one’s butt and GO. Showered, ran to the bank to pick up cash. Spent some time getting the truck started. It was 17 degrees this Saturday morning. Flooded the truck. Ran back home and got starter fluid and got the old beast going. It does run and drive sweet. At last, on my way to Newburg Oregon with the Garmin plugged in and written directions just in case. The Garmin likes to tell me ways to go I don’t agree with. It seems to think the straighter the route the quicker. It eventually caught up with me on I5 south of Portland when it realized my way was indeed the way we were going to go. On a side note the Garmin is a saver. I’ve been utterly lost a couple times when out and about. Within minutes of plugging it in I get unlost.

Got there in good time. Anywhere here in the Pacific Northwest is a pretty drive and I like going places I haven’t been. Looked over the jukebox. The guy had bought it for $800 but really wanted a Rockola. So he didn’t have it long and made a couple hundred. I’m happy, he’s happy and that makes for the best deals.

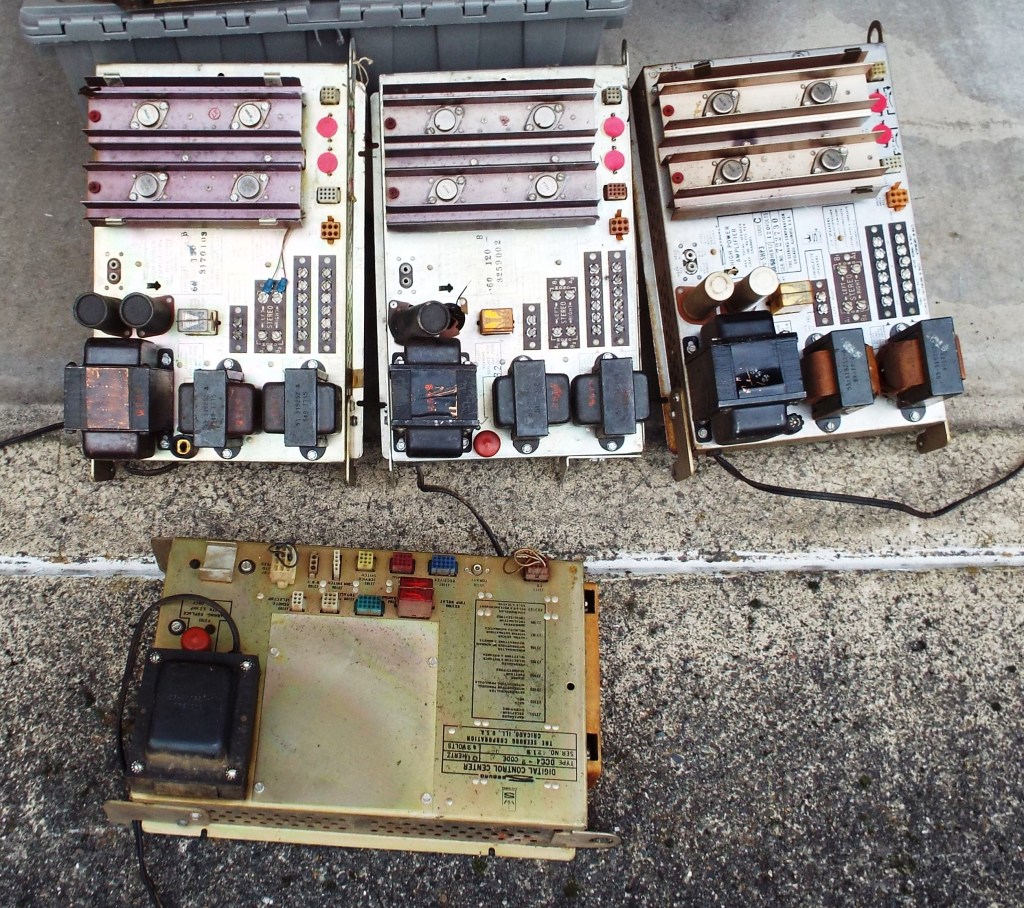

I prepped the jukebox for loading in my truck on its back. I removed the lower back door and put the whole assembly in the cab of the truck. I saw what happened once when someone’s lower back door swung open. It was brought to me for repair. The amplifier and receiver are very heavy. When it falls down wires are ripped and pulled with all kinds of havoc to wiring and plugs. With the lower back door off I used large wire ties and tied all the loose cables to the big 15 inch speaker. This to keep them from getting caught under the cabinet when put on its back. Pulled the records-it came with a full load of 50!!! I’ll go through them and keep whatever I like for the test juke which doubles as my listening jukebox and let the rest go with the C when sold. The only other thing I had to do was make sure the dome was secure. This cabinet has the correct locks and actuators. Someone swapped them side to side to keep them away from actually latching the dome as they most likely did not have a key. I started swapping them around and got one to latch.

It’s about this time when someone watching me work realizes I know a lot more than I let on about jukeboxes. So, I told him what I used to do and now retired continue to do. My money is in his pocket so the price won’t go up or a mind changed at the last second. The last thing I ever want to do is roll up to buy a juke and start spouting about how I’m gonna do this and the juke needs that and I’ll sell it for big bucks etc. Despite the fact that yep….tha’s what I’ma gonna do.

The dome popped open in transit and I found out when I stopped at 7-11 for lunch after about 15 minutes on the road back home. I got lucky. My tool box, a large plastic tackle box, was in the right spot and kept the dome from crashing against the bed of the truck. I secured the dome again, wedged the tool box against the dome and took off with hotdog and drink in hand. The drive back was uneventful and once home I backed into the driveway for the next fun bit. Unloading one of these 300 plus pound jukes by myself can be tough. I did of course get it in the garage and put back together and once my breathe was back to normal got the camera and snapped a few pictures. Then I danced around it while hollering like Tarzan. I quickly realized I should only do this when the garage door is closed, not open to the world passing by who do not understand the thrill of the hunt.

I spent about 10 minutes looking the through the jukebox to get an idea of what need to be done. The mirrors have the incorrect mirror glass with horrible homemade frames. The stainless piece across the upper back door is missing. The upper back door itself looks like a homemade job that they didn’t do too bad on. I’d like to replace it with one having the correct latches and not the two door locks it now uses. I may redo the gold foil inside the cabinet. It had been replaced but someone did not do a very good job. Lots of creases and loose flaps. One of the glass grill tubes is broken. They had it taped together. I’ll replace the blue grill cloth with a sparkly gold cloth that I like to use. And those pilasters! Someone did a decent job, really. Decals of some sort were used. It hides the fact that these pilasters are cracked with one of them having a small hole. The jukebox will look much better with white pilasters. All the animation is missing except the lamp holders. The jukebox has the MRA1 amp used in the B’s and some C’s. I’ll most likely use it unless an MRA3 falls in my hands. I’ll replace the red indicator strip with a white and blue one that will look sharp. The side covers need decals. Little details count as much as the big ones.

The “trick” to these redo restos is to put the juke in 100% condition electrically, mechanically, and cosmetically while trying to spend the least amount possible. Some things can’t be avoided. Those pilasters are $350 dollars for a pair. I’ve already ordered a beautiful mirror set from my friend Johnny Velchoff at almost $200. Another fellow stepped up and said I could have two C’s he has just to get room in his shop. It’s a long drive and even with practically no room in the garage now is an offer I can’t turn down. I can do this juke justice and keep money spent under a thousand. This will allow me a modest profit. But just as important I really like doing what I’m good at and enjoy taking the beginnings of a restoration like this and finishing as it should be. And I don’t have to redo the damned cabinet. It really pops,huh?