HSC Gear Part II

A quick recap. Sean Boyer made 3D gears for the HSC mechanism I was working on. They worked great as replacements for the broken stock gear. I danced a jig. And Scott Walker got the HSC unit he had been dreaming of for quite some time. This is a Home Stereo Console Seeburg made for home use. It holds and plays fifty 33 1/3rd albums. It also has an AM/FM radio with inputs to the amplifier for two more components such as a tape deck or CD player. He is in New York. He arranged shipping and off it went. After he got it and set it up he loaded some LP’s and started enjoying it. I got a message that the mech stopped moving a couple days later. I had wired the mech in place to keep it from moving and stressing the gear so this couldn’t be attributed to traveling from Texas to New York. I had a bad feeling….Thanks to instant messaging and digital pictures it becomes fairly easy to help someone. Especially when they’re willing and have a modicum of mechanical ability. And oh boy! Did he need it. I didn’t think the gear had failed. I showed him a picture of the tool I made to manually move the mech. It’s very similar to the rare Seeburg tool but with a T handle. He made one and the mech still wouldn’t move. So, it could only be the gear. This is a quick write-up but all this action took place over a period of about the last three weeks.

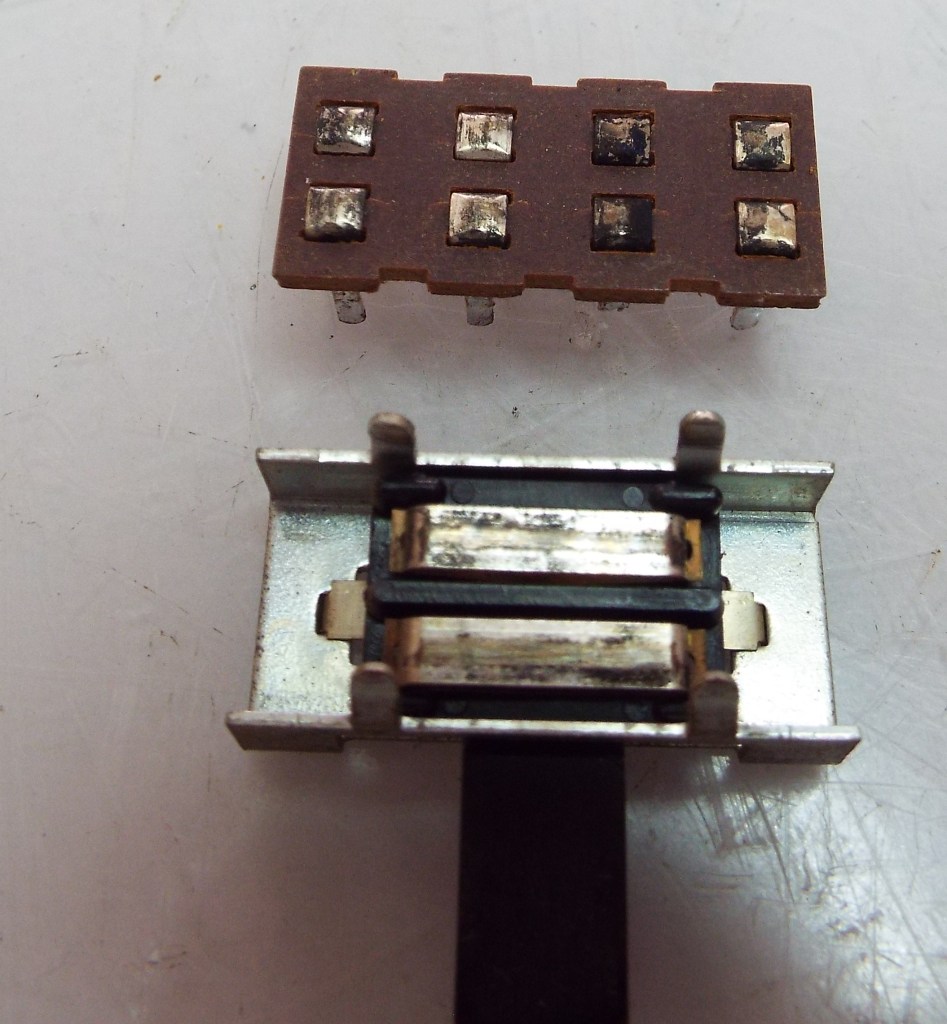

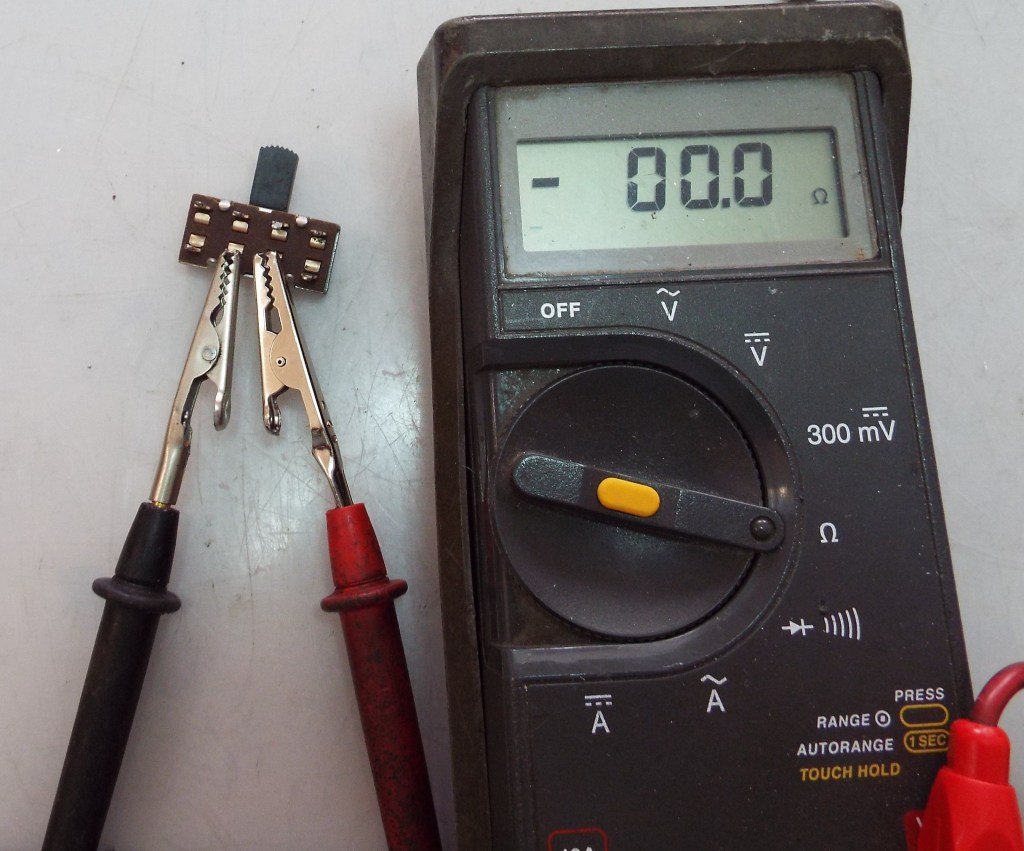

Replacing the reduction gear in the motor isn’t that hard but when you’ve never done it much less know the nomenclature it can be daunting. Several messages and pictures and I walked Scott through replacing the gear. One has to take the rubber belts off, the three screws holding the turntable on, loosen the clutch screws because the motor has a shaft that fits the clutch slot; and to reach the clutch the mech hasd to be all the way left, remove the turntable motor mounting bracket, then the three screws holding the scan motor in and finagle it out past the clutch. Three screws hold the top of the motor case on. I had sent a couple extra gears along for “just in case”. I got him to suspend the mechanism like it is originally suspended. I thought perhaps sitting on a hard surface the mech was transferring too much force to the gear when the mech changed directions. I had one of these in my old shop in Seagoville and well remember hearing the mech swinging about upon direction change.

Scott replaced the gear. It lasted all of two days and stripped. Scott, being a pro at changing gears now handled another replacement with aplomb. I had been back and forth with Sean about this turn of events. He is the maker and hopes to market these gears. He decided to make some out of nylon. It took him less than a week to get several turned out. He sent me nine I think,v and I got several to Scott as quickly as I could. However, the current gear seems to be going strong. It is the same material as the others but a different color. I don’t know if this signifies anything or not. Sean says the red, yellow, and black gears are all the same material but…???

I advised Scott to clean the motor case out real well to get any bits of chewed up plastic out on this last replacement. I’m certain he cleaned and lubed it well. Until the current gear busts we won’t know about the nylon gears for awhile. At least until I haul the HSC 6000 out of storage and start on it. Same basic mech, same control center and selector. It has a different amp/radio in it. Whenever I get the SMC3 done and gone I’ll haul it out.

Kudos to Scott for being so willing to dive in and replace the gear and fix the other little problems that have cropped up.