SMC1 Sold, New home, New Problems

Sold the SMC1 to a lovely couple, Eric and Michelle. They showed up with a small trailer early on a hot Saturday morning. I showed the jukebox and explained various features. Things I had done to it. Reconed speakers, rechromed strips, cleaning, etc. I had picked out 80 records, a half and half mix of C&W and rock n roll for them. When I have them I like to include records as it gives folks something to play right away. Not everyone has 45’s laying around or even knows where to get them nowadays. We agreed on a price and I helped them roll another of my babies down the drive and onto their trailer. I had some misgivings. It was a small trailer not that well-sprung but kept it to myself.

Eric did a fine blanket-wrap on it. This is when heavy moving blankets are draped over the jukebox and then secured in place with those giant saran wrap roller things. Then we started strapping it in with heavy duty trucker straps. We had it tightened down three ways to Sunday. Very solid.

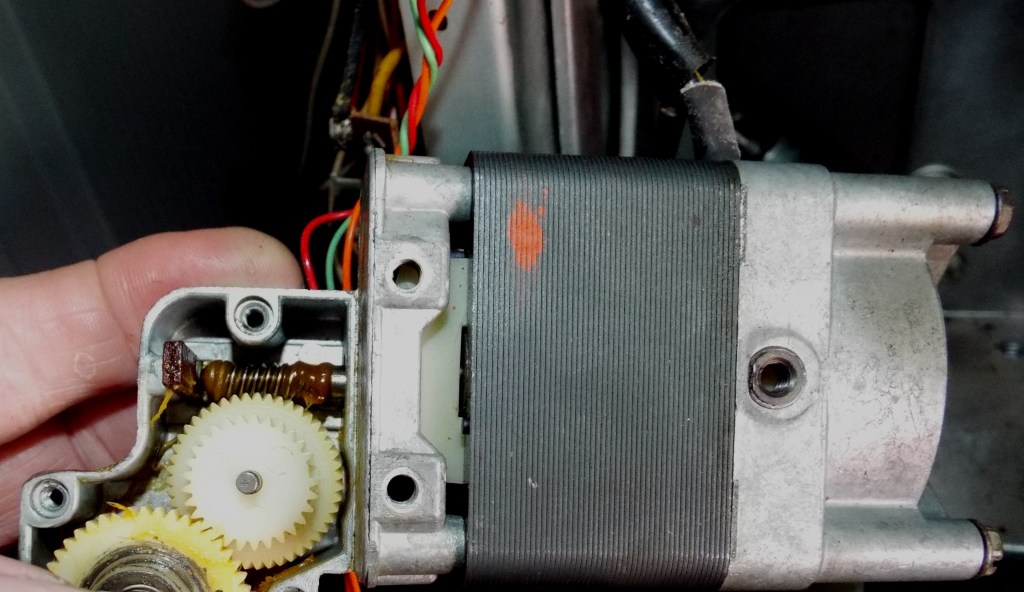

Later that evening I got a notification from Eric. They unloaded it, got it in the house and when the mechanism went to pick up a record it wouldn’t clamp the record!!! We went over a few things on the phone. He was willing to bring just the mechanism to me the next morning so I explained how to remove the mechanism. Luckily the SMC mechanism is probably the easiest Seeburg mech to pull.

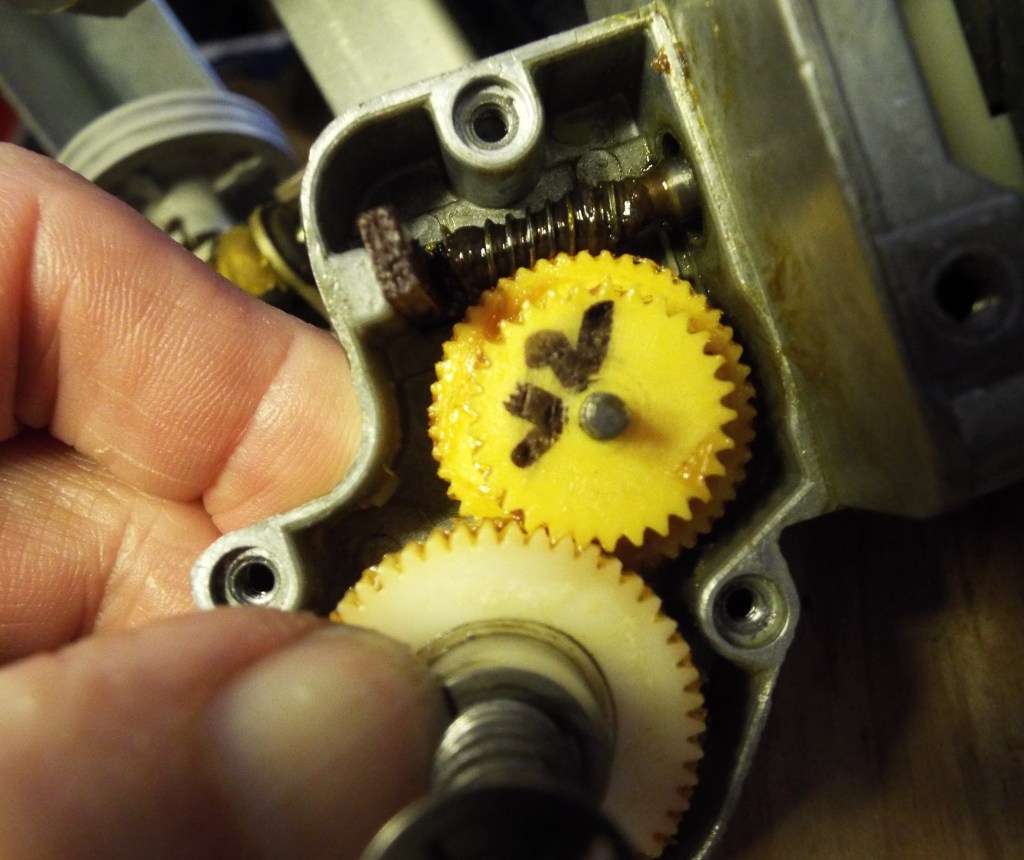

Next morning he brought it by. We got it on the bench. I threw several records in it and connected 115vac to the mechanism harness. This allows me to run this on the bench while tripping the mechanism by hand to simulate operation. The dang-dest thing….the adjustment screw for one side of the record clamp had backed way out allowing the clamp to sit off center. It didn’t take long to get all that straightened out. I think the jukebox got the crap shook out of it riding in that little trailer. Only way something like that could happen. There’s the possibility ol’ Mick didn’t tighten the dang nut on the adjustment screw too well either. I handed Michelle a box of records and asked her to pick out any she liked. I bid them farewell and good luck.

I’m so lucky to have him as a customer. So very patient. So willing to bring the piece back to get it fixed. He lives about an hour away. And of course…that evening the mechanism will do nothing but scan. The computer is all dashes. He checked wiring on the limit switches for me. Reseated the CPU plugs. Even pulled the limit switches to get the mech to switch directions. Something’s still up. What this mech should do upon power up is scan to one end setting a count in the CPU. The display will be all dashes until reset then it shows FP in this case, for free play, and is ready to operate. Something happened to a switch or wire when Eric moved the mech.

I spent the next day getting the SMC3 running. It wasn’t too hard as most of its gear had already been checked out on the SMC1 when I had problems with it. I called Eric that evening and let him know I now have a working SMC3 and will use it to troubleshoot whatever happened to the SMC1 mechanism when Eric has a chance to bring it by. They are out of state escaping the summer heat. I believe he’s bringing the guts to another SMC1 he has back with him. I’ll go through all that as well on the SMC3. It’s nice to have options.