Now that the computers are sorted out it was time to turn my attention to the DEC wallbox add-on to the SMC2 as planned. I keep a good DEC wallbox with cable already connected under the bench. I dragged it out and connected it to a 10 position terminal strip I placed on the bottom of the cabinet on the left side of the mech. The “blue box ” translator goes between the wallbox and the Gen2 board connecting to the wallbox at the terminal strip as well and then plugging straight into the Gen2 board. Three wires go from the PCC to the terminal strip for audio. Only thing left was power. I have several Seeburg light and power transformers. Any 27-30 vac transformer will work. I had all this connected up in a couple hours after dragging all my cables out and sorting them out. I plan to do the same thing, adding a wallbox, to the Hideaway SMC2 when the time comes so this was a little preparation for that project as well.

Comes the big moment, power, lights on the wallbox, Make Selection lamps lit. Punched 111 and the juke played 157. Yep….a few more selections with the oddest results. The two most common selections picked up were 157 and 175 no matter what numbers were punched. If I used the jukebox buttons to select then it operated normally. I disconnected the wallbox from the SMC2 terminal strip and went straight to the STD4 test juke. All selections normal. Wired the wallbox back into the SMC2. Tried the New Gen2 CPU, same results. I started picking all numbers ending in zero trying to establish a pattern. Not really any pattern at all with the former noted most often picked selections being 157 or 175.

I threw the Seeburg MCU into the fray. And out of chaos came order. All selections made with the wallbox using that MCU were normal. So…overwhelming evidence that something was wrong with the two Gen2 boards. I did not want to call Ed and tell the inventor of these boards plus more good things than I know of that his boards were bad. We do speak fairly often but still, I was uneasy. I called and he answered. I said,”I have some bad news. You won’t get angry if I tell you will you?” He laughed,”No, I can’t get mad at you.” I explained what was happening. Something was clearly wrong with the data lines. He wondered if these boards were leftovers from Ron Rich. It didn’t take him long to get his test SMC going using his prototype board. It operated normally. We made some comments about the possibility of components getting changed. He went to the bench where his techs assemble these Gen2 boards and picked one up. After installing it he made a selection and it played some weird number. I said, “Pick 111.” He did and it played 157. Bingo!

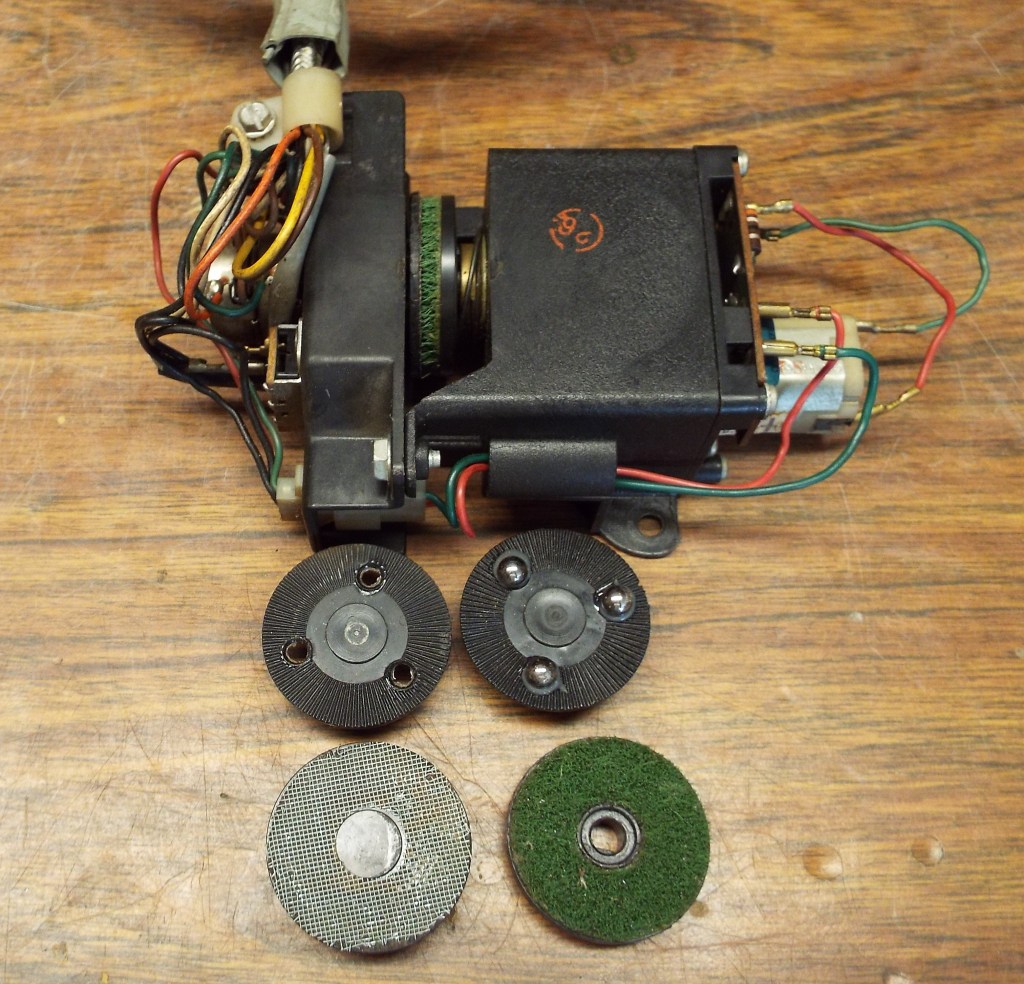

It did not take Ed long to narrow the problem down. I was able to help verify as I had my schematics and the boards out and on the bench in front of me. To make a long story short each input has a .1uf capacitor on it except the four data lines. The speed is in the nansecond range and a cap just sucks that line down. Well, no one knows why but C26 and C28 were supposed to be populated but those caps were placed in C27 Data2 line and C31 Data4 line. I was so happy we found the problem. I’m sure Ed had a lot to say to his assemblers. No telling how many boards went out like that but I had been the first to note the problem. I guess no one is running wallboxes on their SMC’s. He again verified which lines had no capacitors with an email the next morning. I waited until morning when I’d be fresh and repaired both boards in 20 minutes. Both select as they should. Another crisis over.