The New G has a C style pilaster conversion with colored animation. I really like this treatment. Coupled with translucent pilasters it really tricks a G up. Back in the 90’s we used Fred Mlakar’s animation units. He made these for many makes not just Seeburg. These are self-contained light sticks with an animation motor and a color cylinder that popped in place neatly between the caster stud and a slide-in wood plate. The gears fell off the motors in the New G. I really didn’t understand how they were originally attached. Something fell out but I didn’t know what it was. The motor shaft is very thin at 1/8″ and the gear hole is easily 3/16″ maybe 1/4″. I thought of very carefully drilling and threading holes for set screws or perhaps epoxying them on.

Then I got the idea to call the man himself. I had tracked Fred down about five months ago to see if he was still making these animation units. He’s not. He can’t get the correct motors anymore. But, he had two left and was willing to sell them to me. I’ll use them for a 100C coming up someday. I explained my problem and solutions to Fred and he told me what he does. He does not use set screws; tried those; they’re noisy and vibration is transmitted through the cabinet and can affect the sound. What he does or did was quite unique and he had special tooling made to be able to install a rubber sleeve made of surgical tubing into the gear shaft hole and then what he called a D spring into the rubber sleeve. The D piece fits tightly over the moter shaft mating with the flat side. You might have seen these type of “springs” on any number of press fitted knobs. Fred said he still had the tooling and to send the gears to him and he would repair them. This was extremely generous of him and sure got me out of a jam. I imagine he was curious to see them as well. It had only been 30 some years. They will be in the mail tomorrow without fail.

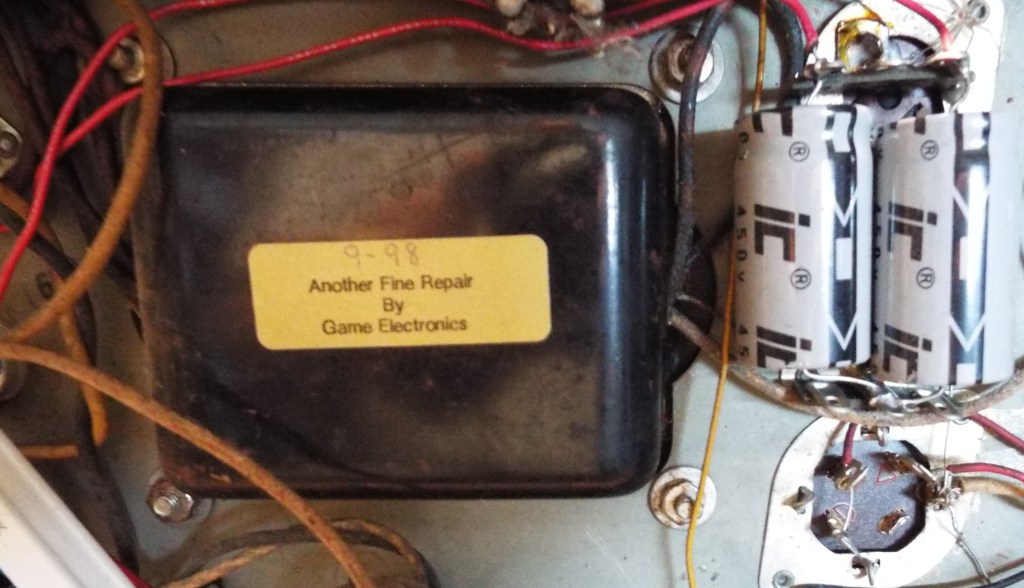

The SMC1 amplifier, a SHP3, got recapped the night before and now was time to bench test.It had no burned resistors or bad transistors. Very straightforward refurb. I cleaned the bias pots, set bias and fired it up. Very weak left channel that I tracked down to a loose connection on the pre-amp board. Once that was fixed I ran it for awhile keeping an eye on the bias. It was rock solid-didn’t wander. Put it in the SMC1. I’ve written very little about the SMC1. The mech has already been washed and serviced. I’ve got a good MCU for it. The PCC and the MCU were tested in another SMC. With the amp done it’s time to test it. I seem to be attracting them lately. I have another SMC1 and a SMC2 in the wings.

Got my Victory Glass order. This always feels like Christmas. The premier piece was the SMC2 bottom glass. This is a new piece for Victory and it is a stunner. After the SMC1 is done then it’s on to the SMC2. I also ordered mech cover inserts for the G and the upcoming C plus classification sets, selection indicator strips,record rack number strips, a back door decal set, some motor couplers, Nidec motor mount conversion rings, and a couple of stripper plates one of them complete. I could not believe the crappy finish on the brush holders for one of the stripper plates. I’ve seen 50 year old originals that looked better. Called Jim at VG and he asked for pictures. Took a few and sent them. Got a call back, yep they were pretty bad. He’s sending another set. Victory will take care of you and I trust them. I found out they finally made some C pilasters and was able to order a set of the white translucent ones. Poor guys, I had only been bugging them for a couple months.